In aerospace domain

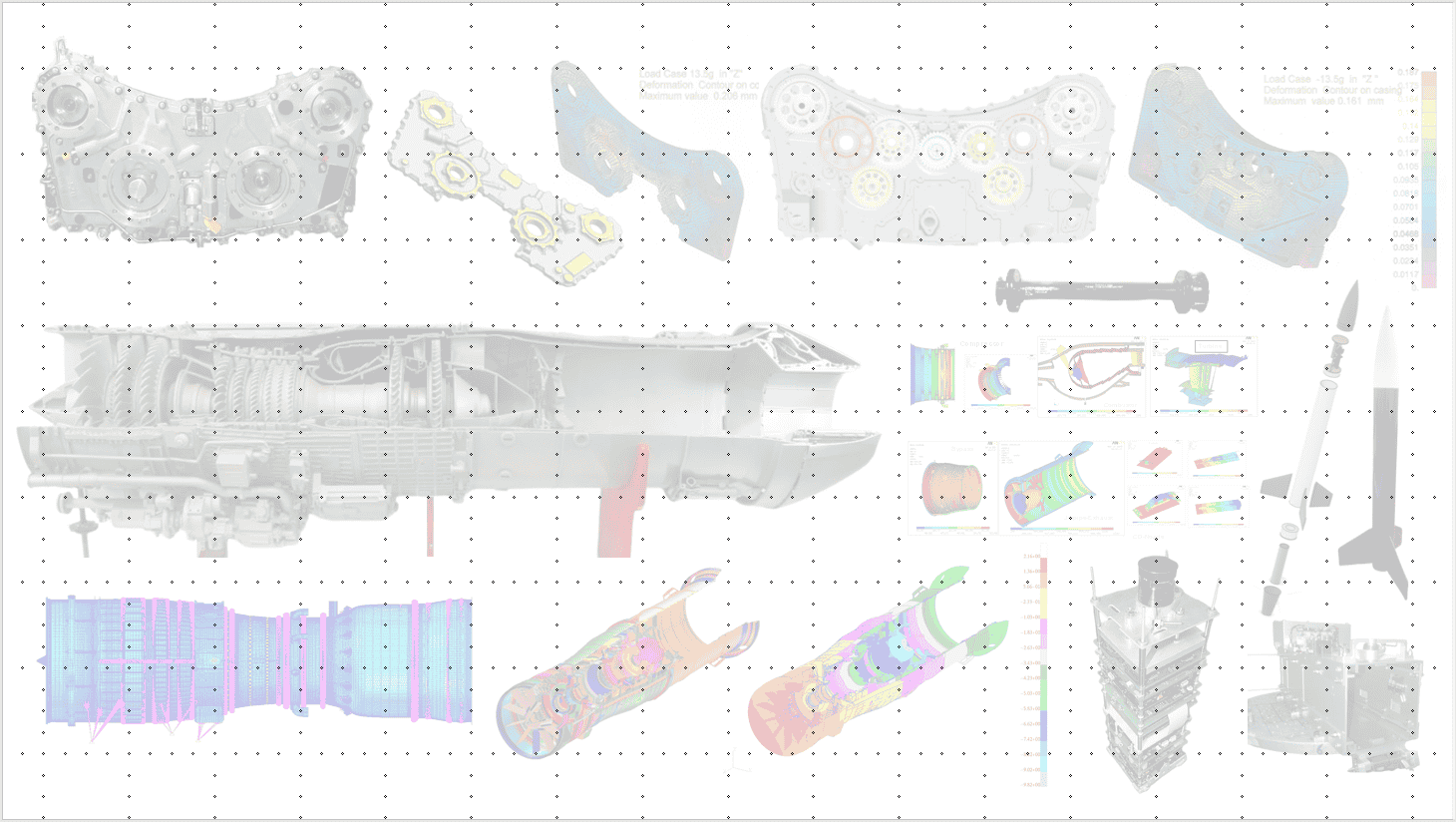

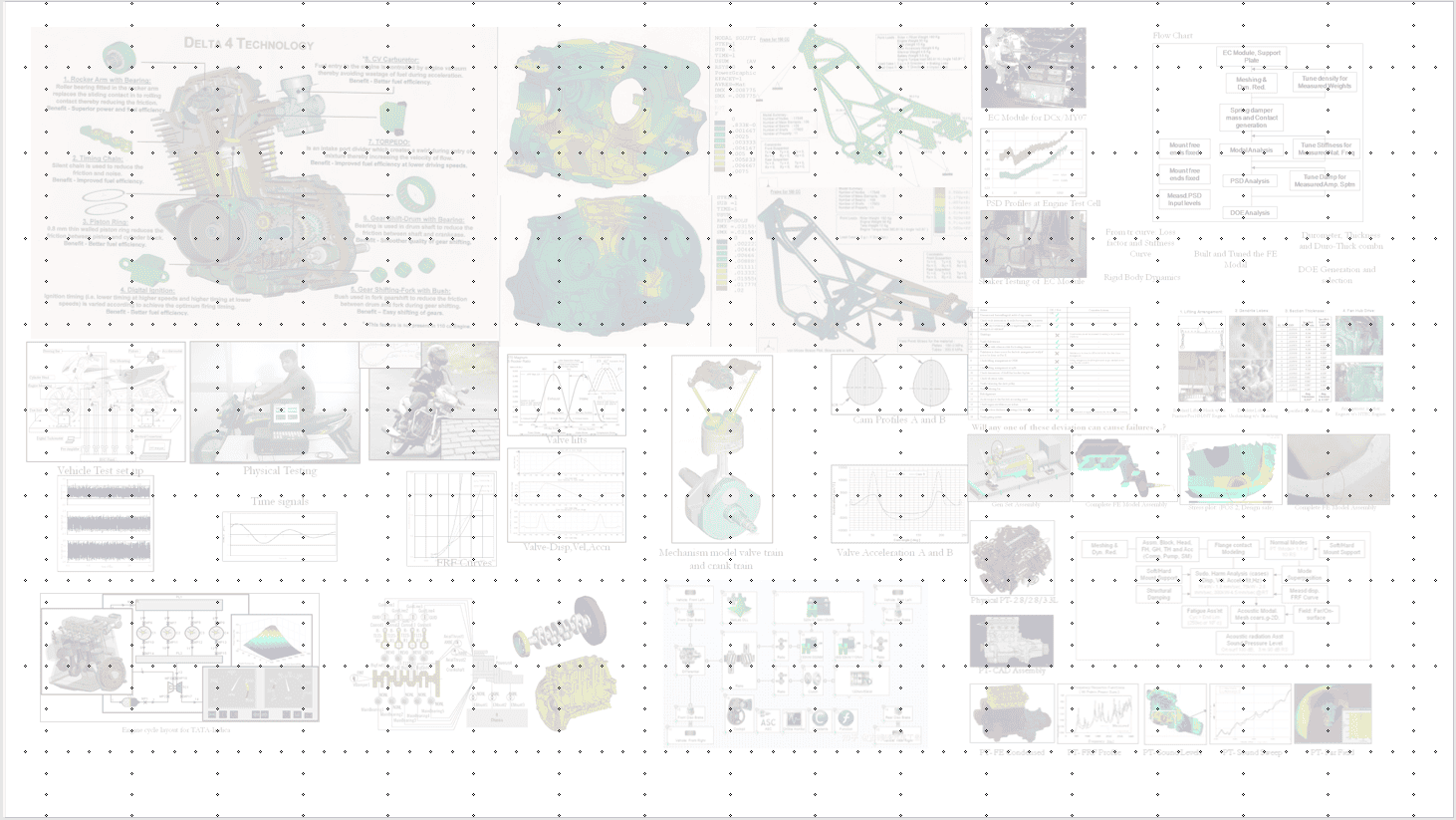

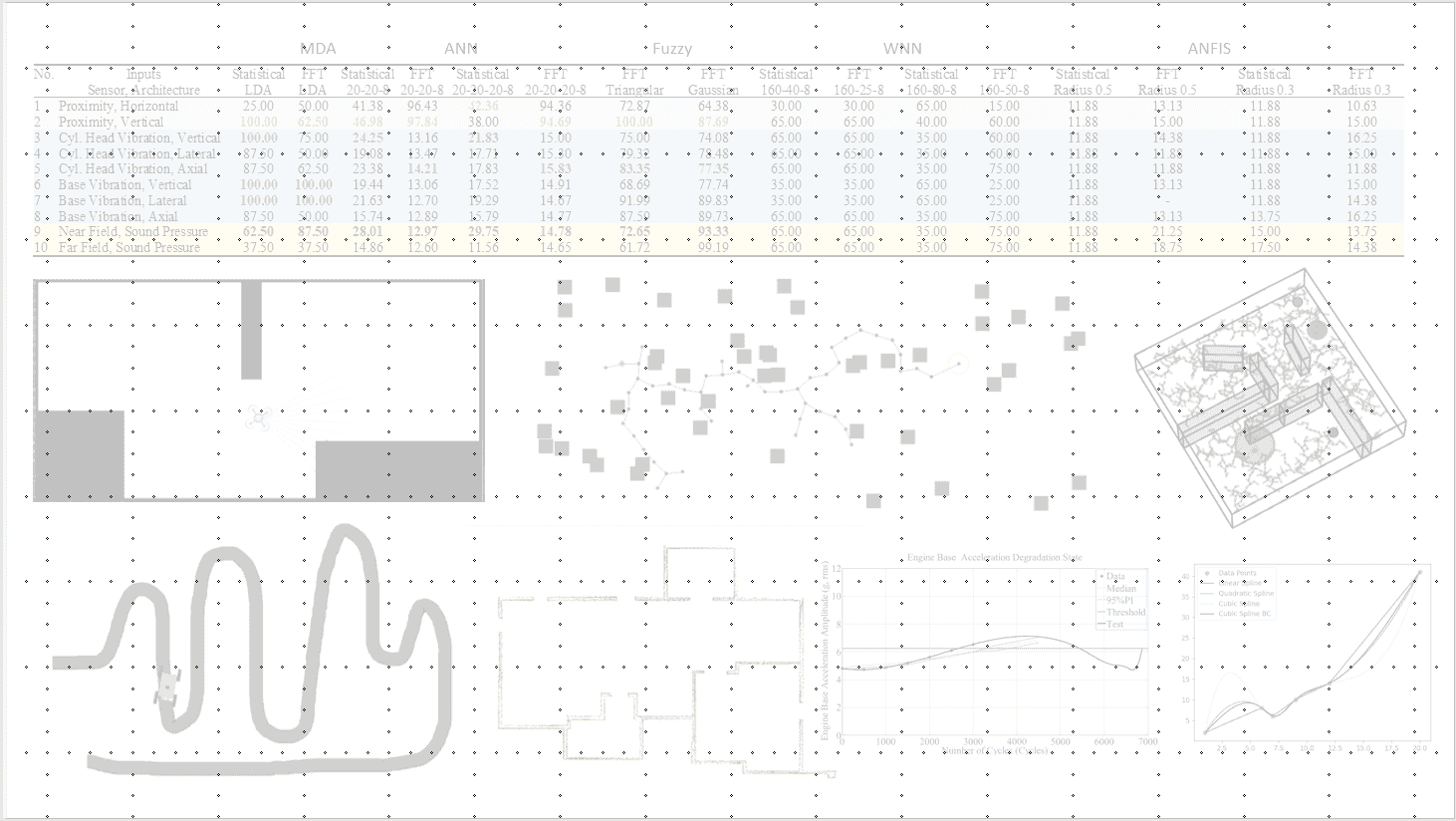

Dr. Prashanth's aviation career started in the late 90s, supporting the initial phases of the Light Combat Aircraft (LCA) programme. He worked for the design validation and weight optimization of Aircraft Mounted Accessory Gear Box (AMAGB), which was the first time designed and developed in the country with technical objectives such as lightweight, compact, high speed, single input, and multi-output gearbox. He also worked for the design validation of the Power Take Off (PTO) shaft, the Secondary Power System (SPS) of LCA Tejas, coupling the engine-mounted accessory gear box with the aircraft-mounted accessory gear box. He facilitated the DRDO's attempt to develop an indigenous powerplant for the LCA by supporting the structural analysis and weight optimization of the aero engine at the component and integrated levels. He supported the life prediction of a gas turbine bladed disc project. He mentored the student teams for the design and development of UAVs.

In space career, he has mentored the student team for the design and development projects. He was associated in reviews and external examiner. He was with the group for design and development of Indias first nanosatellite.

EXPLORE NOW